Whatever your industrial drying system is, Nortegas adapts to you

Industrial dryers are used to remove water and different liquids from any product, and use heat to do so.

Industrial drying systems depend on 3 main factors:

- The air speed.

- The relative air humidity.

- The temperature of the chamber.

If those factors are controlled, the drying speed and quality can be determined, along with the degree of humidity of the product from which the liquid has been removed.

If you are considering a change of system or a new installation, we have a team of experts to advise you.

Just call us on 900 902 933 or request your personalised quote.

We have the solution

Thanks to natural gas, the chamber temperature can always be controlled, which means more efficient drying systems and, in turn, better drying quality.

Efficiency and savings

Industrial drying systems that use natural gas as the energy source to heat the chamber are particularly recommendable to be used in urban areas, as their fuel is clean.

Natural gas is also very cheap, compared to electricity or diesel.

Please do not hesitate to consult our team of industrial specialists for further information on possible savings with respect to other fuels. Contact us by calling 900 902 933.

How do they work?

There is an optimum drying procedure for each product, and to determine it, we must take into account different aspects of the product and conduct an adaptation study in order to find the suitable system.

When determining this procedure, the 3 main drying factors will also have to be taken into account in addition to the product-related aspects:

- Air speed. The humidity given off from the product surface is transported in the air. The faster the speed, the greater carrying capacity, but if too much air is applied, the product surface can dry up, which can hinder or even stop the drying process.

- Relative air humidity. This refers to the relationship between the amount of water vapour in the air with respect to the maximum possible. The higher the temperature, the greater the capacity of the air to contain water vapour, in other words, the air can absorb a large amount of water from the product to be dried. In the same way, extracting water vapour from the air lowers its relative humidity and thus increases the drying capacity.

- Temperature of the chamber. The temperature makes the value of the relative humidity of the air vary and also, consequently, the capacity of the air to extract the humidity from the product. Furthermore, the speed of the water molecules accelerates as the temperature rises, encouraing the vaporization process and help the vapour to move from the centre of the product to its surface.

Main advantages

Natural gas is a leading alternative for industrial drying systems, as it allows the air to be heated directly, offering optimum drying conditions in aspects of hygiene and safety, and at a low price.

Furthermore, as the treated products are not contaminated, natural gas is the best option for processing agri-farming and food products.

Additional advantages

Industrial drying systems that use natural gas also offer the following additional advantages:

- Accurate temperature control and of the generated flows.

- Quick response to extra spikes in demand or constant start-up and shutdown operations.

- They occupy less space than the facilities that operate with other fuels.

If you are considering a change of system or a new installation, we have a team of experts to advise you.

Just call us on 900 902 933 or request your personalised quote.

More common types of dryers

Rotary dryer

It is the universal type of drying. It is a rotary drum in which the product and drying thermal fluid are put. It uses a high temperature.

There are two types of plants depending on the thermal fluid: direct drying and indirect drying.

- Direct drying: the hot gases are directly introduced in the trommel.

- Indirect drying: it uses hot air as thermal fluid.

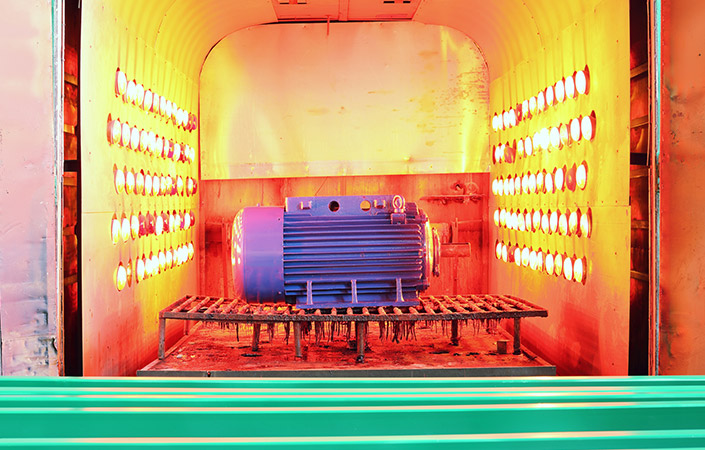

Tunnel dryer

It is mainly used in the food industry. It is a tunnel where hot air is introduced to dry the products.

Chamber dryer

It is used to dry pharmaceutical and chemical products, on products, with hot air.

Tubular dryer

It involves putting the product in the drum through a hermetic valve. The drying occurs as the product slides through a bundle of hot rotating tubes. The liquid evaporates from the products and is absorbed by the drying air.

Column dryer

These dryers consist of a vertical column down which product is lowered. The products are mainly corn, soya, sunflower seeds, coffee, rice, etc., in other words, ones with a high granulometry.

As the product goes down, it passes through hot air and the humidity is thus absorbed. It is sometimes expelled to another area where it is cooled using cold air.

Installation or adaptation

Nortegas will help you with the installation in the most efficient way possible.

If you do not have natural gas installed, but you have a butane or propane gas installation, you will just need for the burners to be adapted and certified by an authorised installer.

If, on the other hand, you do not have any type of installation, we will provide a personalised study and adapted to your needs, thanks to our team’s extensive experience.

Finally, if you already have natural gas installed, we will help you to adapt your installation to the new drying ovens.

If you are considering a change of system or a new installation, we have a team of experts to advise you.